GreenSwitch® Nitrate is the world-first patented process based on Pure Green Agriculture technology turning manure into organically derived Nitrate fertilizers for the high-tech greenhouse sector and open-field fertigation. GreenSwitch® encourages smart-farming practices, opening a new horizon for more sustainable agriculture and precision crop nutrition.

GreenSwitch® Nitrate, fertilizing a green future!

Based on Pure Green Agriculture technology, the GreenSwitch® Nitrate process produces sustainable soluble Nitrate fertilizers with a negligible carbon footprint. Unlike other organic fertilizers, the GreenSwitch® Nitrate process goes one step further and produces Nitrogen, coming from animal manure in the form of Ammonium (NH4), in Nitrate form.

GreenSwitch® is a completely new Nitrate production process in which energy consumption is reduced by more than 90%. It will also give organic certified farmers and conventional high-tech growers the tool they need to apply Nitrogen for immediate uptake and manage crop nutrition better while reducing their carbon footprint and nitrogen (ammonia) emissions significantly.

This project was made possible by the Dutch Ministry of Economic Affairs and Climate Policy.

What makes GreenSwitch® Nitrate sustainable?

The first step in reducing emissions from agriculture is to produce food as efficiently as possible by using all available resources with a minimal impact on the environment and improving crop nutrition.

The GreenSwitch® Nitrate production process has been proven* to be close to zero Carbon footprint. The CO2 footprint is reduced by more than 95% and is proven through the SNK report (following the Paris Agreement COP21). By applying GreenSwitch® Nitrate fertilizer to their crops, growers reduce the CO2 impact of their activity. Moreover, the electricity that is used in the GreenSwitch® Nitrate production process is green energy coming from the biogas process.

As an answer to sustainable agriculture needs, GreenSwitch® Nitrate adopts a circular economy model in its approach. By creating a circularity between the livestock sector and the conventional agriculture sector, GreenSwitch® Nitrate shifts agricultural practices with the twofold objective of reducing the production of by-products and the impact on the environment.

GreenSwitch® closes the Nitrogen cycle: no Nitrogen from the air and no Nitrogen into the air. Within this circular economy framework, the re-use of waste products as input for crops brings new opportunities to close the loops in agriculture and improve the efficacy of the biogas industry.

Agriculture -especially livestock and manure- is responsible for 59% of total Nitrogen emissions as Ammonia form (NH3). Ammonia is a colorless gas, lighter than air, and easily volatilize into the atmosphere. As a usual practice, growers tend to use the remaining Nitrogen in the manure as fertilizer. Due to the high concentration of Ammonia, this method has a detrimental impact on the environment.

GreenSwitch® Nitrate contributes to solving the Nitrogen deposition problem of the dairy, pig, and poultry industries. In the GreenSwitch® product, Nitrogen is present in the form of Nitrate, and therefore, there is no NH3 emission into the atmosphere. The Nitrogen emission in the air of GreenSwitch® Nitrate is null. By re-cycling the liquid fraction of the manure, we avoid the Ammonia present in this fraction being released into the air.

Nitric Nitrogen, the most effective form for fertigation in conventional agriculture, is now suitable for organic farming. GreenSwitch® Nitrate is Organic Farming certified* in certain countries and currently in-process of registration in some others. Here's an overview:

- Today, GreenSwitch® Original is Organic Farming certified for America (NOP standard via Ecocert)

- GreenSwitch® Original is currently in the final stage to get Organic Farming for America (NOP standard via OMRI), Australia (ACO standard via Acos), and Japan (JAS standard via Kiva)

*To know if GreenSwitch® Original is already registered in your country, please contact your sales agent.

I’ve been part of several projects, related to green fertilizers, but one question we always came back to was is it possible to produce sustainable soluble nitrate fertilizers.

Phil van WakerenCEO of Pure Green Agriculture

Phil van WakerenCEO of Pure Green Agriculture

What to know about GreenSwitch® Nitrate?

Located in the East of The Netherlands, installations include a co-digester factory that transforms manure into biogas (1000 m3 per hour), green electricity (2000 kW/hour), and liquid CO2.

GreenSwitch® Nitrate is a joint project between Van Iperen International, Pure Green Agriculture, and Agro Energie Hardenberg. This strategic partnership is intended to support the transition towards sustainable agriculture with the highest quality products and a minimal impact on climate.

Pure Green Agriculture is our R&D partner. GreenSwitch® Nitrate is based on Pure Green Agriculture technology. As equipment supplier, Pure Green Agriculture holds a patent for the ART and AIR process.

Agro Energie Hardenberg is in charge of production. Its installations offer a co-digester combined with heat and power (CHP), in which biomass is processed into electricity (used for the GreenSwitch® Nitrate production process).

At Van Iperen International, we care for the industrialization and commercialization of GreenSwitch® Nitrate products worldwide. Our sister company, Van Iperen, is an exclusive distributor of GreenSwitch® Nitrate fertilizers in The Netherlands.

How GreenSwitch® Nitrate production process works?

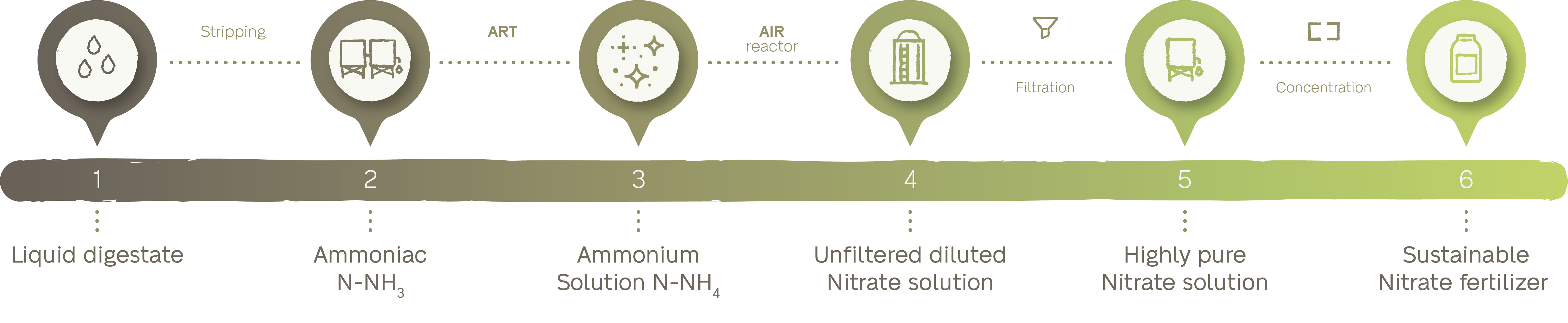

How GreenSwitch® Nitrate production process turns manure into sustainably produced Nitric Nitrogen-based fertilizer:

- The manure is collected after a co-digestion process

- Ammonium is stripped from the manure in a closed stripper and run through the ART to get a ammonium solution

- In a bioreactor (AIR) bacteria are converted from ammonium into nitrate resulting in nitrate

- The nitrate solution is filtered

- The nitrate solution is concentrated

- The final pure and transparent nitrate fertilizer is ready to use

GreenSwitch® Original HG: our first solution!

GreenSwitch® Original HG is a unique, pure, and transparent Nitric Nitrogen and Potassium solution. Our product is stable and recommended at different phenological stages. GreenSwitch® Original HG is a 2 - 0 - 7 formulation, offering a sustainable alternative for mineral Nitrate formulations -like Potassium Nitrate or liquid equivalents- to the conscious grower.

- Unique liquid organic Nitric Nitrogen (Nitrate)

- Nitrogen directly available and assimilable by the crop

- Close to zero carbon footprint circular patented production process

- Developed for open field, pot production, and soilless application