GreenSwitch® Potassium is a fossil fuel-free production process, up-cycling residues from electric car batteries and the paper and pulp industry. The final product is GreenSwitch® Potassium Sulphate, a premium and fully water-soluble Potassium Sulphate with significantly reduced CO2 emissions suitable for foliar and fertigation applications. Produced in Sweden by our industrial partner CINIS Fertilizer, GreenSwitch® Potassium Sulphate is marketed by Van Iperen International.

Life Cycle Assessment (LCA) available under request.

What makes GreenSwitch® Potassium process unique?

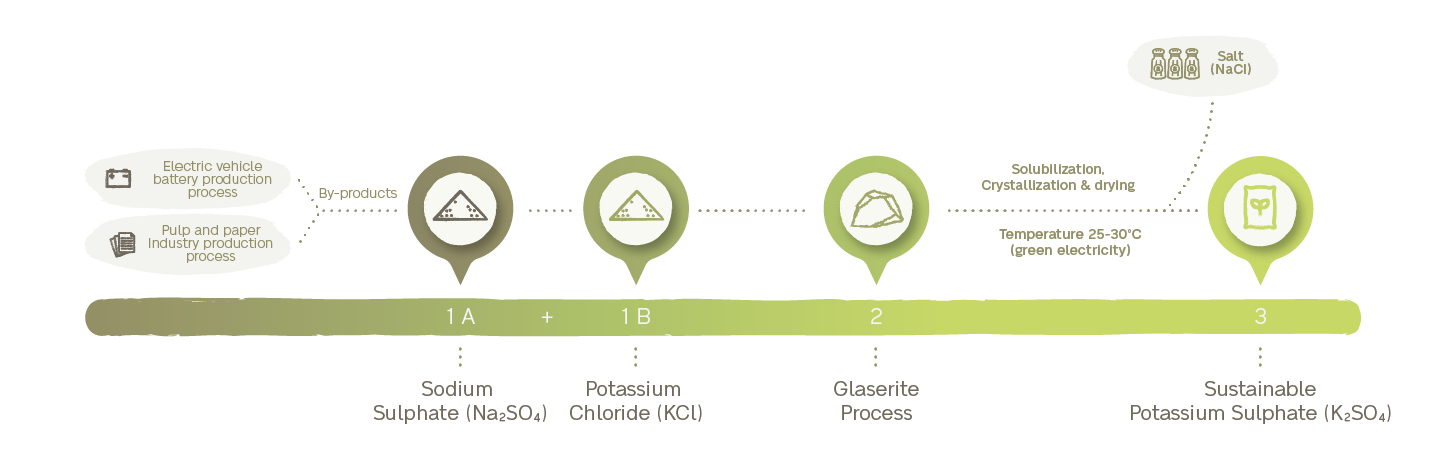

The GreenSwitch® Potassium process, based on CINIS Technology, is grounded on using residues from other industries, including ashes from pulp mills and Sodium Sulphate (Na2SO4) from electric car battery manufacturing. These industries are looking for sustainable ways to handle their by-products, and with the increasing demand for electric cars in the years ahead, the recycling of their residue is becoming an increasingly crucial issue. This method of using residues as raw material in the production process of Potassium Sulphate is one-of-a-kind worldwide and is protected by a patent.

Compared to the standard, the GreenSwitch® Potassium process runs at low temperatures (25-30 oC) and low pressure resulting in less energy consumed.

The GreenSwitch® Potassium process is based on green hydroelectrical power.

In case of extra heat, it will be sold to the grid for district heating. All the water that is consumed in the process is entirely recycled. Besides Potassium Sulphate, the GreenSwitch® Potassium process generates Sodium Chloride (NaCl), commonly known as salt or table salt or used to de-ice roads. It’s a totally safe, sustainable, and commercial by-product.

The process itself, the circularity, and the use of green energy guarantee the lower carbon footprint of the GreenSwitch® Potassium process.

A full LCA (Life Cycle Assessment) of the GreenSwitch® Potassium production process has been done to provide certified data on the carbon footprint.

GreenSwitch® Potassium process: A circular and sustainable production process

In short, the patent-protected process uses waste from other industries – ash from pulp and paper mills and waste salts (Na2SO4) from electric car battery manufacturing – to produce a circular and fossil-free fertilizer, water-soluble potassium sulphate (SOP). The production process runs on green electricity and recycles all water. Cinis Fertilizer’s process will have lower energy consumption.

New business partnership

Van Iperen International aims to introduce new sustainable technologies in crop nutrition and distribute that through its global marketing network. Jakob Liedberg, Founder of CINIS, explains: “Fertilizers bring huge benefits to agriculture and society, but producing them is heavily dependent on fossil fuels. We are very happy to make a crossed-sector alliance with electric vehicle batteries and pulp and paper industries on our mission to close the loop on recycling useful industrial waste. The goal: producing a fossil fuel-free high-quality fertilizer with significantly less negative climate impact than today’s standards.”

GreenSwitch® Potassium Sulphate Horticultural Grade, the final product

GreenSwitch® Potassium Sulphate HG is the first water-soluble Potassium Sulfate fertilizer produced through an environmentally friendly circular process with a minimal carbon footprint in Sweden. Our trusted industrial partner, CINIS Fertilizer, produces it. GreenSwitch® SOP is a highly pure Potassium fertilizer, which dissolves rapidly and completely. Like conventional Water Soluble SOP, GreenSwitch® SOP can be used in any fertilization program for high-tech greenhouse and open field fertigation as well as for foliar application. Our product is not sensitive to caking and is recommended during fruit or tuber development and up until maturation, and during coloring of fruits. The high potassium level in our formula plays an essential role in achieving higher-quality yields.

Growers using GreenSwitch® products reduce their Carbon Footprint and bring waste back to life. With GreenSwitch® Potassium Sulphate, growers make the switch to sustainable high-tech agriculture.

Available now!GreenSwitch® Potassium Sulphate, another step in our Green Switch Journey!

GreenSwitch® Potassium Sulphate (SOP) is part of the innovation projects to support our Green Switch Journey. With this journey, we want to bring our contribution to increasing the sustainability of global agriculture, both greenhouse horticulture, and open field. How? With Plants for Plants®, GreenSwitch Nitrate®, and GreenSwitch Potassium®.

By creating less polluting production processes such as GreenSwitch® Potassium, we can provide the growers with sustainable, reliable, and efficient solutions, chemically identical to the products currently used in high-tech agriculture and horticulture. Now, let's make the green switch!